Stainless Steel Cutlery Production Line

Are you tired of dealing with slow, inefficient, and outdated spoon/fork/knife manufacturing processes that are costing you time, money, and valuable customers?

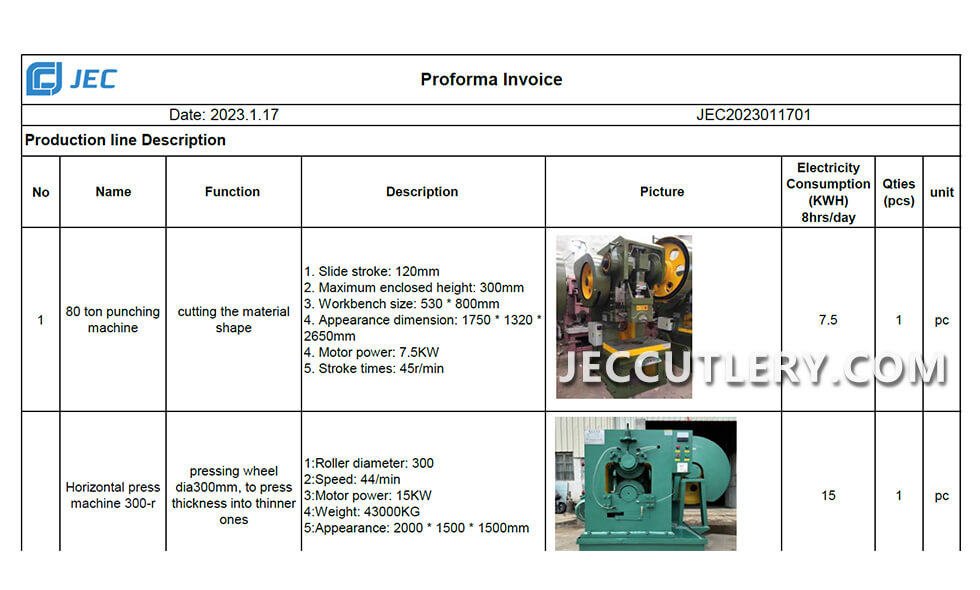

Upgrade your manufacturing process with our stainless steel cutlery production line! Our advanced technology will transform your manufacturing process, producing high-quality flatware faster and more efficiently than ever before. You’ll be able to keep up with demand and ensure that your customers are always happy with their purchases.

How To Get The Best Inquiry

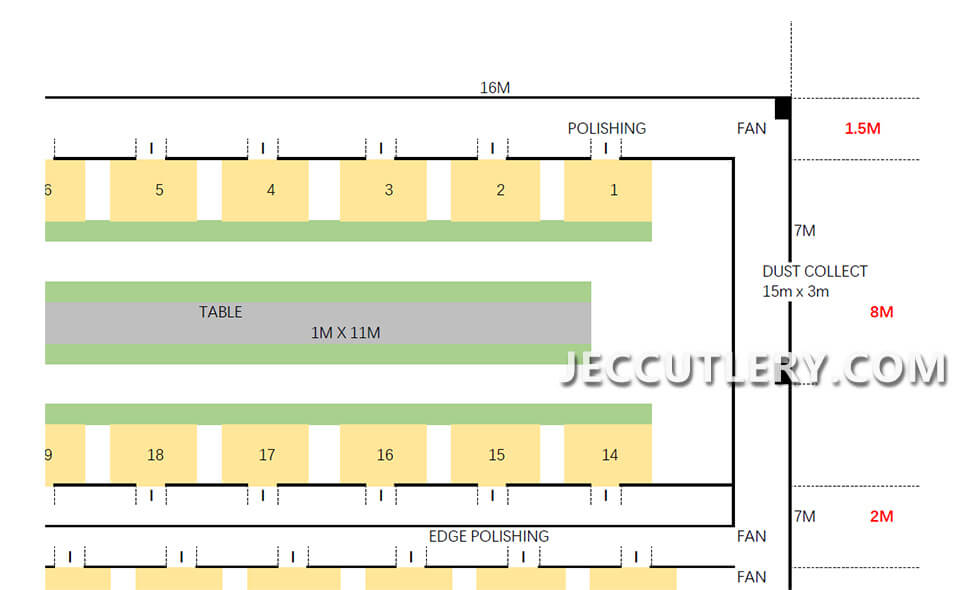

What Are The Processes Included?

Different grades of cutlery items request different production solutions. The expert engineers’ team can provide the best suggestion base on your samples.

FAQ Of Cutlery Making Machine Line

Ready To Upgrade Your Industry?

Any customized needs? Please feel free to contact us.