Punching Press Machine

Are you looking for a solution to speed up and simplify your cutlery making process without sacrificing quality?

Offer you a perfect solution for cutlery pressing with our punching machine. With its advanced technology and simple user interface, the machine can help you create flatware with amazing accuracy and speed. Whether you’re a small business owner or a large-scale manufacturer, our machine is the perfect addition to your workshop.

What Are The Features Of Punch Press

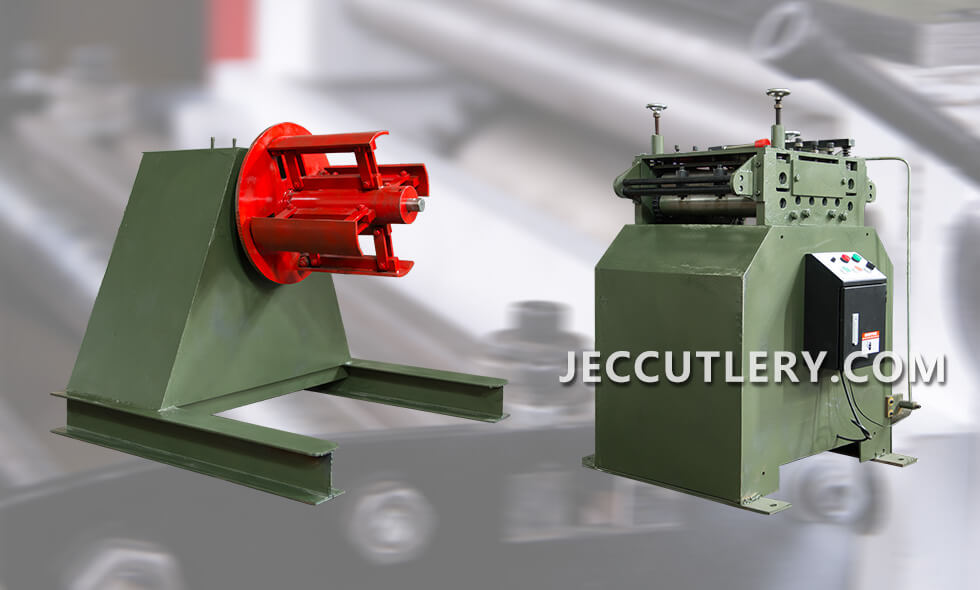

How Great Work With Auto-feeder

With automatic option, you can produce high-quality cutlery quickly and efficiently. Revolutionize your production line and increase your output by up to 200%.

How To Choose The Right Press Model

For more detailed specifications, please feel free to contact us. Or send us your samples, our engineering team will give you the best choice.

| Name | Unit | J23-25A | J23-40A | J23-63A | J23-80A | J21-100A |

|---|---|---|---|---|---|---|

| Nominal force | KN | 250 | 400 | 630 | 800 | 1000 |

| Nominal stroke | mm | 5 | 6 | 8 | 9 | 10 |

| Slide stroke | mm | 80 | 120 | 120 | 130 | 140 |

| SPM | min-1 | 60 | 55 | 50 | 45 | 38 |

| Max die height | mm | 180 | 220 | 270 | 290 | 320 |

| Die height adjustment | mm | 70 | 80 | 80 | 100 | 100 |

| Between slide center and frame | mm | 210 | 260 | 260 | 270 | 380 |

| Bolster (F·B*L·R) | mm | 400*600 | 480*710 | 480*710 | 520*860 | 710*1100 |

| Bolster opening (up dia*depth*low dia) | mm | φ120 | φ220*25*φ180 | φ220*25*φ180 | φ200*45*φ180 | φ260*50*φ220 |

| Bolster thickness | mm | 70 | 80 | 90 | 100 | 120 |

| Bed opening (Dia*F·B*L·R) | mm | φ180*130*260 | φ200*150*300 | φ250*200*340 | φ250*200*340 | φ320*250*420 |

| Slide area (F·B*L·R) | mm | 210*250 | 270*320 | 280*320 | 280*380 | 420*560 |

| Shank hole (Dia*Depth) | mm | φ40*70 | φ50*70 | φ50*80 | φ60*75 | φ60*80 |

| Main motor power | KW | 2.2 | 4 | 5.5 | 7.5 | 7.5 |

| Outline dimension (F·B*L·R*H) | mm | 1325*990*2140 | 1600*1180*2310 | 1810*1350*2640 | 1810*1410*2790 | 2250*1650*3030 |

Ready To Upgrade Your Industry?

Any customized needs? Please feel free to contact us.