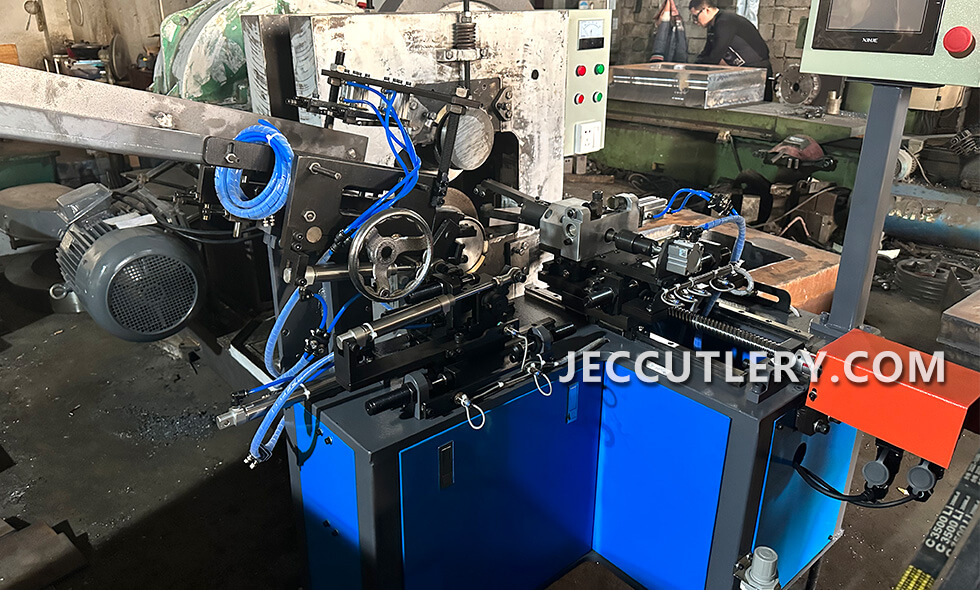

Automatic Feeding Machine

Cutlery manufacturers! Ready to ditch the manual feeding madness and unlock the secret to flawlessly crafted SUS spoons/forks/knives?

Look no further than our servo automatic feeder! it eliminates repetitive manual labor, providing a safer and more comfortable working environment. Its consistent, high-quality stainless steel cutlery pieces will flow effortlessly, exceeding customer expectations and boosting your reputation.

Discover Advantages Of Automatic Feeders

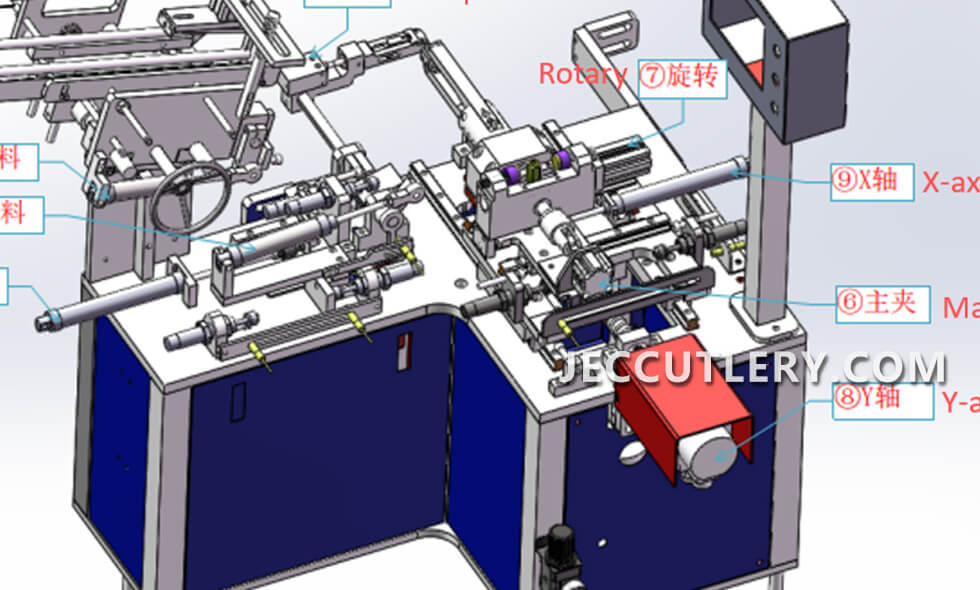

How Great The Auto-Feeding Machine For Press Machines and Cross Rolling Machine

With automatic manipulators, production is up to 99%. One feeder with a press machine could process 28-32 pcs/min of flatware, and one feeding machine with the cross roller could operate 55 times/min of cutlery.

Types Of Automatic Manipulators

For more details, please feel free to contact us. Tell us your requests, our team will give you the best solution

| Name | Automatic Feeder Of Press Machine |

|---|---|

| SUS material thickness | 1-7mm |

| SUS material length | 100-220mm |

| Motor power | 220V 20W |

| Shut height of press machine | ≥195mm |

| Name | Auto-Manipulator Of Cross Roller |

|---|---|

| SUS 304/201 material thickness | 0.9-8mm |

| SUS 430/420/410 material thickness | 0.9/10mm |

| Motor power | 2.6kw |

| AC servo motor | 1.2kw |

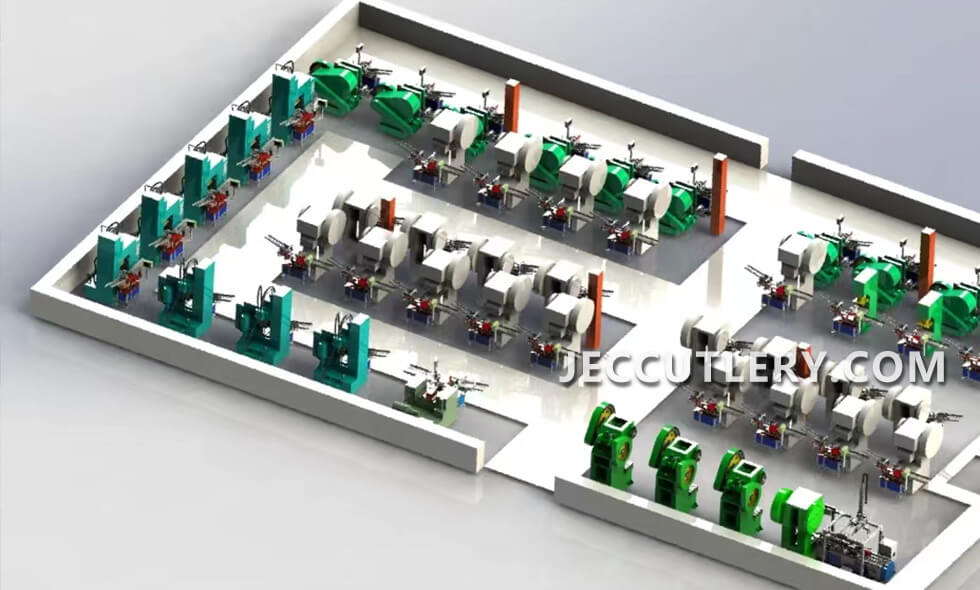

How Well The Automation Of Polishing Line

The fully automatic polishing machine can make full use of the original polishing space and equipment for modification. It occupies less land, is digitally controlled, and is easy to operate. It is flexible and can operate in groups. One worker can arrange materials to operate a complete polishing line.

Details Of Polishing Auto-Machine

More information, please contact us anytime. Show us your samples, we will give you the best project.

| Name | Automatic Feeder Of Polishing Machine |

|---|---|

| Voltage | 220V |

| Processed items | 60-400mm |

| Power | 24v, 4.5kw |

| Machine size | 1300-1600*850*930mm |

| Weight | 480kg |

Ready To Raise Your Industry?

Any customized needs? Please feel free to contact us.