Which Hydraulic Press Machine Design Is Best For Your Production Line

A quick overview of the topics covered in this article.

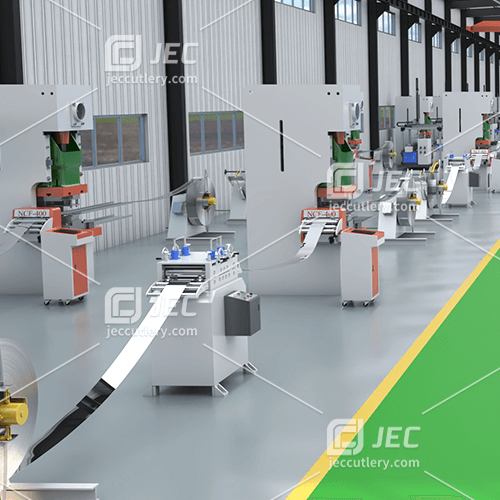

Hydraulic press machines are indispensable tools in various industrial sectors, offering immense force and precision for forming, shaping, and molding materials. Selecting the appropriate hydraulic press design is crucial to ensure optimal performance and efficiency in your operations. In this article, we delve into the intricacies of different hydraulic press designs and provide insights on how to make the right choice for your specific needs.

What Are The Types Of Hydraulic Presses And Their Different Characteristics?

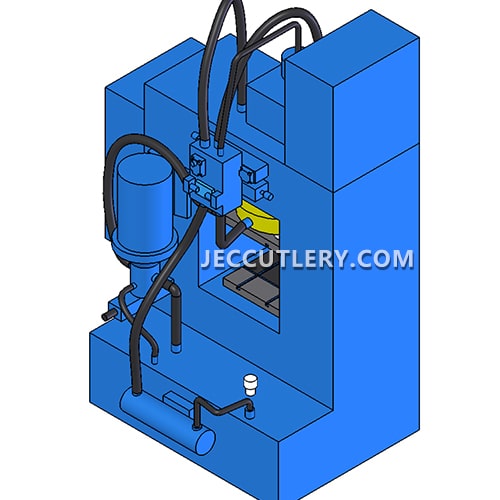

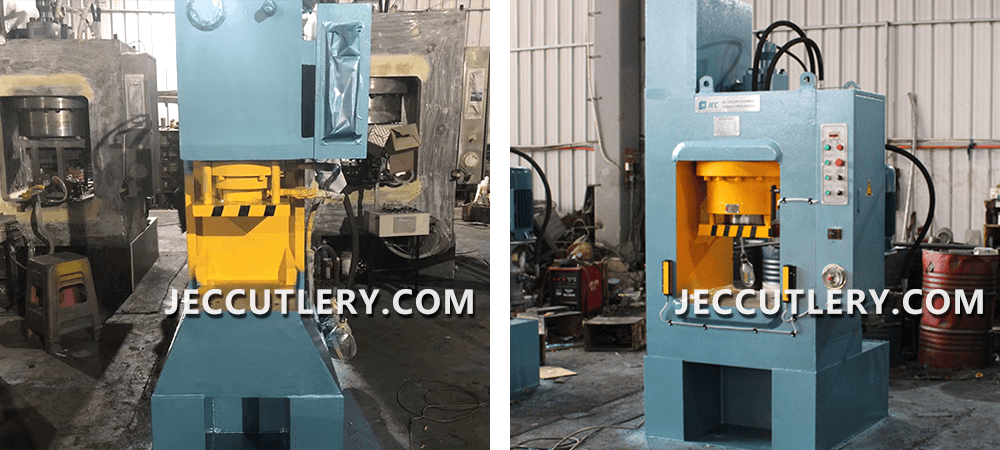

- C type hydraulic presses, feature a C-shaped frame structure that provides accessibility and versatility in operation. These presses are widely favored for their compact footprint, making them suitable for applications with space constraints. The open design of C type presses facilitates easy loading and unloading of workpieces, enhancing productivity and efficiency on the shop floor. Additionally, their simplified construction allows for straightforward maintenance and servicing, minimizing downtime.

- In contrast to C type presses, H Frame hydraulic presses boast an H-shaped frame configuration, which offers superior rigidity and stability during operation. This design provides enhanced support and resistance to deflection, making H type oil hydraulic presses ideal for applications that require high precision and consistent performance. The robust construction of H type presses enables them to withstand heavy loads and intense pressure, ensuring reliable operation even in demanding

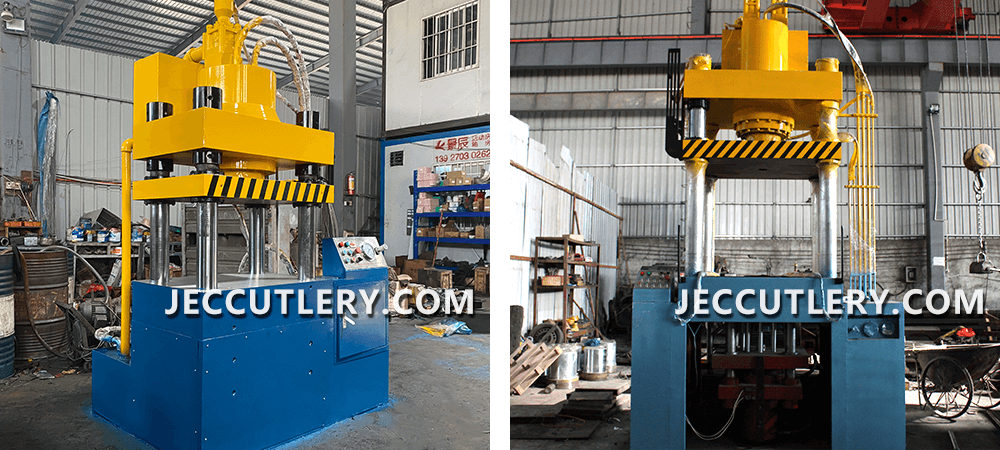

- Four-column hydraulic presses, also referred to as pillar presses, feature a four-post frame design that delivers exceptional strength and durability. The presence of four vertical columns ensures uniform distribution of force and minimizes deflection, allowing for precise and consistent forming operations. These oil press machines are commonly used in applications that involve heavy-duty workpieces or require deep drawing capabilities. The robust construction of four-column presses enables them to withstand high tonnage requirements, making them suitable for tasks such as metal forming, forging, and stamping.

- Deep drawing hydraulic presses are specifically designed for shaping sheet metal into complex and intricate components with deep-drawn features. These pressing machines utilize a specialized tooling setup, including a blank holder and die, to gradually stretch and form the material into the desired shape. The deep drawing process requires precise control over parameters such as pressure, speed, and tool alignment to achieve accurate results.

What Are The Factors For Selecting Right Hydraulic Press Design?

- Operating pressure and force

The operating pressure and force capabilities of a hydraulic press are critical factors to consider when making your selection. Determine the maximum force required to perform the intended tasks and ensure that the chosen press design can deliver the necessary tonnage. Additionally, consider factors such as speed, stroke length, and ram velocity to optimize the performance of the press for your application.

- Bed size and throat depth

The bed size and throat depth of a hydraulic press play a significant role in determining its suitability for various workpieces. Assess the dimensions of the parts you will be working with and choose a press design that offers adequate bed size and throat depth to accommodate your requirements. Ensure that the press provides sufficient clearance and accessibility for loading and unloading operations, especially for larger or irregularly shaped workpieces.

- Maintenance and servicing requirements

Regular maintenance and servicing are essential for ensuring the long-term performance and reliability of hydraulic presses. Consider the maintenance requirements of different press designs, including accessibility for inspection and servicing, availability of replacement parts, and ease of troubleshooting. Choose a press design that offers convenient maintenance features and reliable support services to minimize downtime and maximize productivity in your facility.

Practical Applications Of Different Hydraulic Machines

- In the automotive industry, hydraulic presses play a pivotal role in manufacturing various components, including body panels, chassis parts, and engine components. The high-volume production requirements and diverse part geometries often necessitate the use of robust and versatile hydraulic press designs such as H-frame or four-column presses. These presses provide the necessary force and precision to form complex shapes with consistency, meeting the stringent quality standards of automotive manufacturers.

- In the manufacturing of household appliances, hydraulic punch presses are employed for forming metal components, plastic enclosures, and structural elements. The versatility and cost-effectiveness of C-frame and H-frame presses make them popular choices for producing a wide range of appliance parts, from stamped sheet metal components to molded plastic housings. These presses enable manufacturers to achieve high productivity and consistency in producing appliance components while maintaining competitive pricing in the market.

- Hydraulic presses play a vital role in the production of cutlery and kitchen utensils, shaping various materials such as stainless steel, aluminum, and plastic into functional and aesthetically pleasing products. The stability and high force capability of H-frame hydraulic presses make them particularly well-suited for manufacturing cutlery, ensuring uniformity in shaping and consistent quality across production batches. Conversely, deep drawing stetching hydraulic presses are preferred for manufacturing kitchenware such as pots, pans, and baking trays, enabling the formation of intricate shapes and deep cavities required for these products while maintaining uniform thickness and high-quality finishes.

In conclusion, choosing the right hydraulic press design is a critical decision that can significantly impact the success of your manufacturing operations. By understanding the unique features and capabilities of different designs and considering factors such as their application requirements, you can make an informed decision that meets your specific needs and goals. Invest the time and effort to evaluate your options to ensure the hydraulic press you choose can deliver the performance, efficiency and reliability your production process requires.

A quick overview of the topics covered in this article.