How To Integrate Cutlery Automatic Polisher And Cleaner

A quick overview of the topics covered in this article.

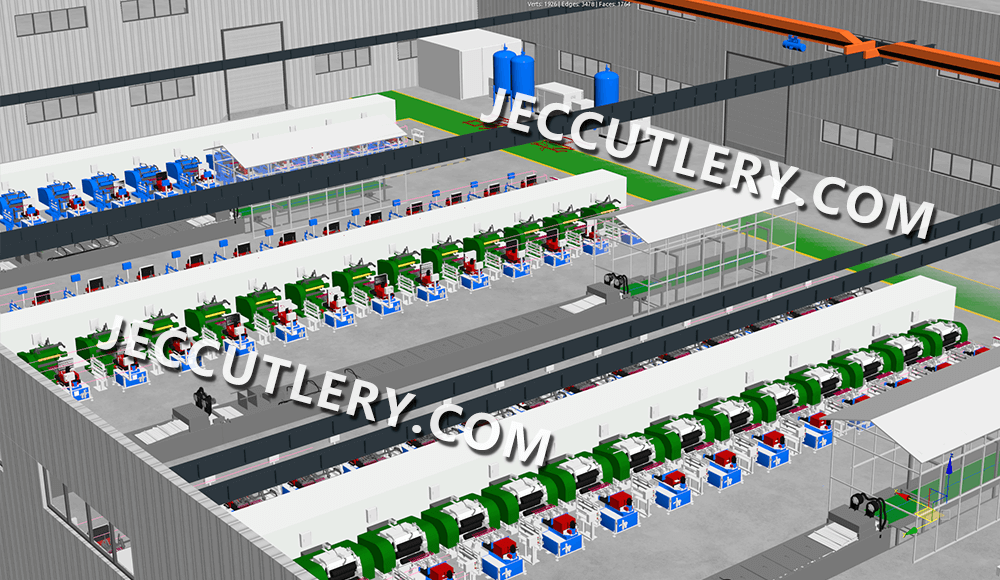

The stainless steel cutlery industry is always evolving. Automation is at the forefront of this change. If you make high-quality cutlery, you know it must have a flawless finish and be clean. These are non-negotiable. But how do you integrate automatic polishing and cleaning machines to streamline production? Let’s break it down.

What Benefits Does Automatic Polisher Provide For Cutlery?

Hand-polishing stainless steel cutlery takes a lot of time and effort. It often leads to mixed results. That’s where an automatic polishing machine comes in. The key benefits of automation include:

- Consistent Quality: Automated machines polish with perfect precision, reducing human error.

- Time Efficiency: These machines can operate without interruption, which accelerates the polishing process.

- Cost Savings: You can cut costs by reducing manual labor.

- Durability: Automatic machines are built to last. They need few repairs.

For manufacturers, a machine that always delivers a perfect finish is a game changer.

How Does Ultrasonic Cleaner Improve Cutlery Cleaning Efficiency?

When it comes to cleaning, ultrasonic technology is taking things to the next level. Ultrasonic cleaning machines use high-frequency sound waves. They create tiny bubbles that reach every nook of your dishes. The bubbles break down grease and dirt without harsh chemicals.

Here’s why ultrasonic cleaning works so well:

- Precision Cleaning: Ultrasonic waves can reach areas that traditional methods can’t. So, every piece of cutlery is spotless.

- Efficiency: The process is quick and thorough. You can clean large batches of cutlery in less time.

- Eco-Friendly: Ultrasonic cleaners often use less harsh chemicals than conventional methods.

For businesses that must be both clean and productive, ultrasonic cleaning is a must.

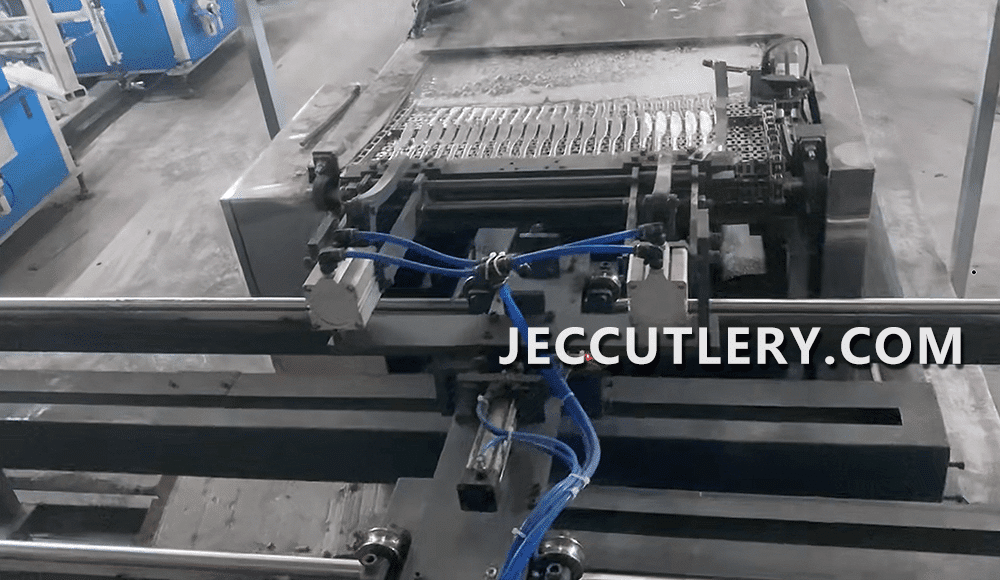

The Role OF Spray Cleaner In Automated Cleaning Process

Ultrasonic cleaning does the deep cleaning. Spray cleaners are key in the automated process. They add a layer of cleaning efficiency. These machines use high-pressure nozzles to spray clean water onto the cutlery. This removes any remaining contaminants.

The benefits of spray cleaners include:

- Targeted Cleaning: Spray cleaners can focus on areas that need extra attention.

- Fast Drying: Many spray cleaners have systems that speed up drying. This ensures that cutlery is ready for the next stage of production.

Spray cleaners and ultrasonic cleaners work hand in hand. They form a robust cleaning system for your cutlery production line.

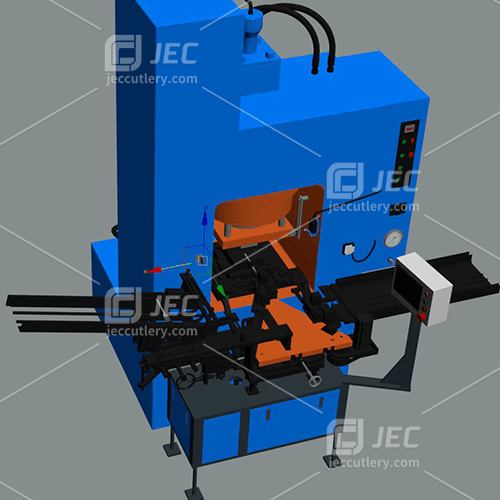

How Can Polishing and Cleaning Machines Be Connected In A Fully Automated Process?

A seamless production line requires integrating your polishing machine with your cleaning machines. Use a fully automated system. It will sync the machines into one, continuous workflow.

Here’s how it works:

- Automated Conveyors: They move cutlery from the polishing machine to the cleaning station. This eliminates the need for manual handling.

- Programmable Logic Controllers: They manage the timing and coordination between machines. This ensures that everything operates without issues.

- Minimal Downtime: Connecting the machines reduces transition time, boosting productivity.

Automating the whole process from polishing to cleaning speeds up production. It also ensures consistent quality.

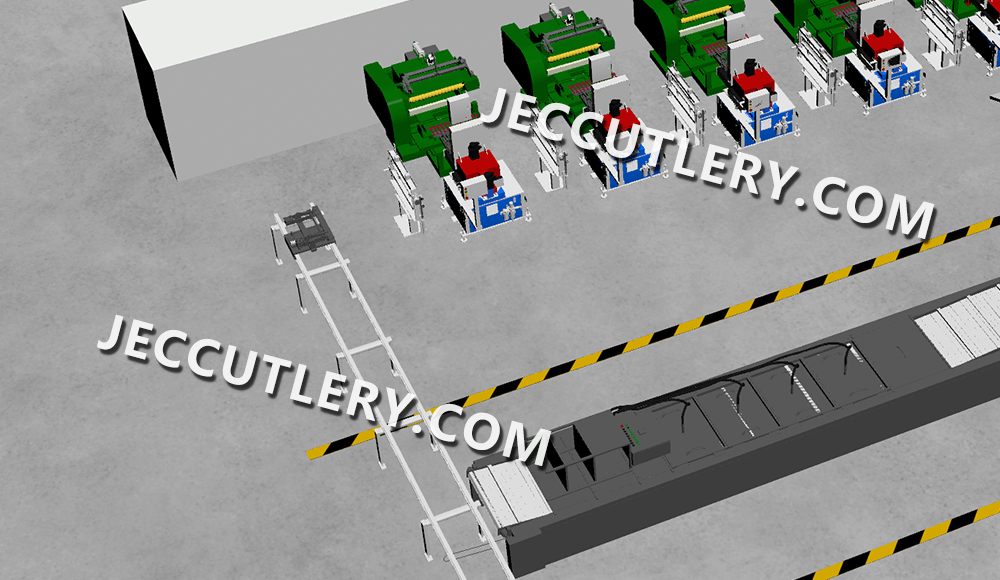

How To Choose A Fully Automatic Polishing And Cleaning System?

Automation has clear benefits. But there are cases where manual polishing may be better. Manufacturers can choose from several options to automate polishing and cleaning. Each option has its pros and cons depending on the production scale.

- Manual machines: they offer flexibility but are labor-intensive.

- Semi-Automatic Machines: They mix manual control with automation. They are ideal for small to medium-scale production.

- Fully Automatic Machines: The best choice for large operations. They are very efficient and need little human intervention.

Ultimately, the right machine depends on the operation’s size and the desired control.

In conclusion, automation in stainless steel cutlery production is now essential. Automatic polishing machines and ultrasonic cleaning technology help manufacturers. They save time and cut costs. These tools deliver consistent, high-quality finishes far faster than manual labor.

Investing in the right equipment helps companies boost productivity and cut costs. Proper maintenance also reduces environmental impact. Automation isn’t just about faster production; it ensures top-quality cutlery every time.

A quick overview of the topics covered in this article.