5 Tips for Improve Your Stainless Steel Cutlery Production Line

A quick overview of the topics covered in this article.

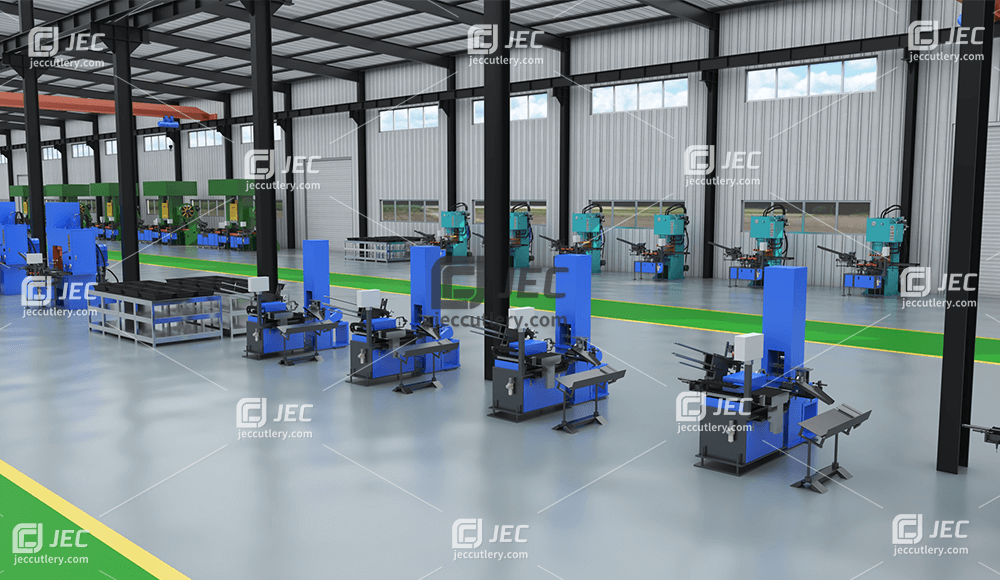

Running your stainless steel cutlery production line at greatest efficiency reduces costs. It increases production and maintains high quality. Outdated equipment combined with inefficiencies can reduce your business’s operational potential. This write-up shows five key ways to improve your production line. These tips can help your business grow faster in the cutlery market.

The steel cutlery optimization process has three main parts:

- Optimizing operations

- Improving machinery

- Using new technology

Using these five tips helps manufacturers create automated systems. This improves product quality and increases production efficiency.

1. Streamline operations with automation

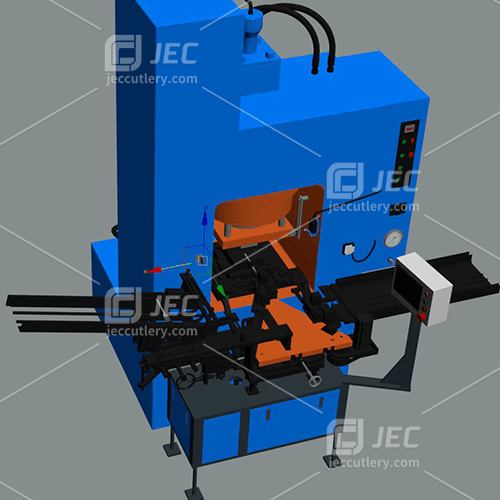

Automating your production line is the most effective way to improve performance. Production schedules face delays, while processing times also become slower due to manual labor that can lead to human errors. Investing automatic hydraulic press machines will increase your manufacturing speed and precision.

Automated system integration helps businesses cut labor costs and boost productivity. This allows for higher output with fewer resources. Automated systems ensure both production line competitiveness and high-quality production standards.

2. Upgrade to high-quality press machines

Using old or aging press machines can affect production runtime and result consistency. Switching to modern punch presses and hydraulic presses will make your operation more efficient. Due to their high build quality, you will see greater precision and efficiency. Modern equipment achieves high-volume production with minimal downtime. This leads to stable production results.

High-quality presses can reduce defects and improve the quality of stainless steel flatware. Press machines with modern technology save energy and cycle quickly. This provides lasting cost benefits to operators. These machines are a smart choice for companies that want to boost production and cut costs.

3. Enhance surface finishing with polishing machines

The appearance of stainless steel cutlery is the main reason for attracting consumers. A high-quality surface finish makes products look better. It also improves durability and functionality. Your tableware needs a polisher to achieve its smooth appearance and even shine.

Automatic polishing and cleaning machines will enhance your production line. They ensure the quality of all items. Automatic machines remove the need for manual polishing. This makes your finishing process faster and reduces defects. Automatic systems ensure consistent products and even finishes. This improves product quality and makes customers more satisfied.

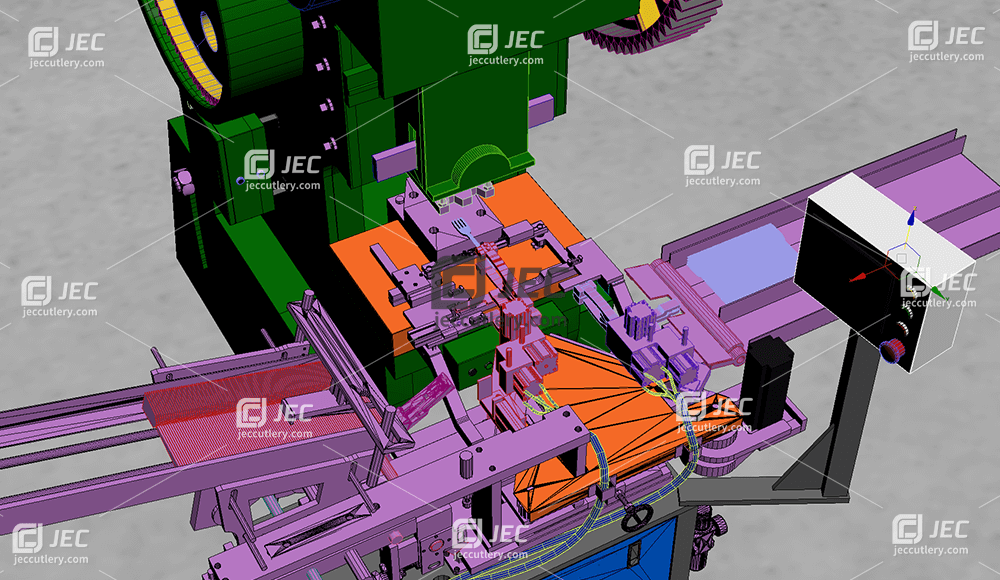

4. Optimize mold design for durability

Your production line relies on good mold design for maximum efficiency. Your custom molds for stainless steel cutlery make production better and cheaper. They also ensure precise results. If molds have poor designs, it can lead to more waste. This means longer production times and higher manufacturing costs.

5. Focus on effective quality control systems

Quality control systems are essential for making stainless steel cutlery. A strong quality control system takes your market quality to the top. This system helps you deliver defect-free items, ensuring you provide the best products.

There are three key steps to organizational quality control:

- Check raw materials often.

- Supervise the active process.

- Test the finished product thoroughly.

Manufacturing quality control systems use visual inspection tools and precise measurement equipment. They catch defects early in production. This helps avoid costly mistakes and the need for rework. Your brand stays strong when you ensure quality throughout production.

In conclusion, Optimizing your stainless steel cutlery production line is key. It improves productivity and cuts costs, leading to better quality output. Investing in automation and new press machines will increase your output. Better surface finishing, improved mold designs, and stronger quality control systems will help. These changes will help your business compete better. They also meet the growing demand for premium stainless steel products.

A quick overview of the topics covered in this article.