How Are Forks Made: A Complete Manufacturing Guide

A quick overview of the topics covered in this article.

Forks are a staple in our daily lives, yet we seldom think about how these everyday utensils are made. This guide shows you how stainless steel forks are made. It starts with choosing the materials and ends with the final product on your dining table.

What Materials Manufacturing Stainless Steel Forks?

The journey of a fork begins with its raw material—stainless steel. This alloy is popular for cutlery because it is strong, durable, and resists corrosion. Stainless steel mainly contains iron, chromium, and nickel. Chromium stops rust. The most common type for forks is 18/10 stainless steel. It has 18% chromium and 10% nickel, which makes the forks strong and shiny.

Key Steps In Making Stainless Steel Forks

Making stainless steel forks involves several steps. Each step is important for the final product:

- Raw Material Preparation: Start the process by getting high-quality stainless steel sheets or rods. Check them to ensure they meet standards before production begins.

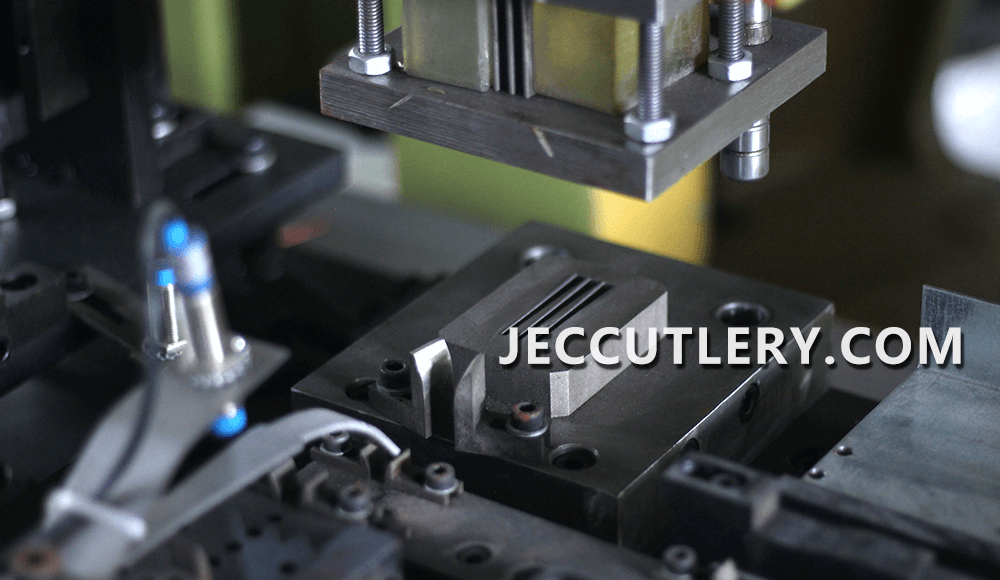

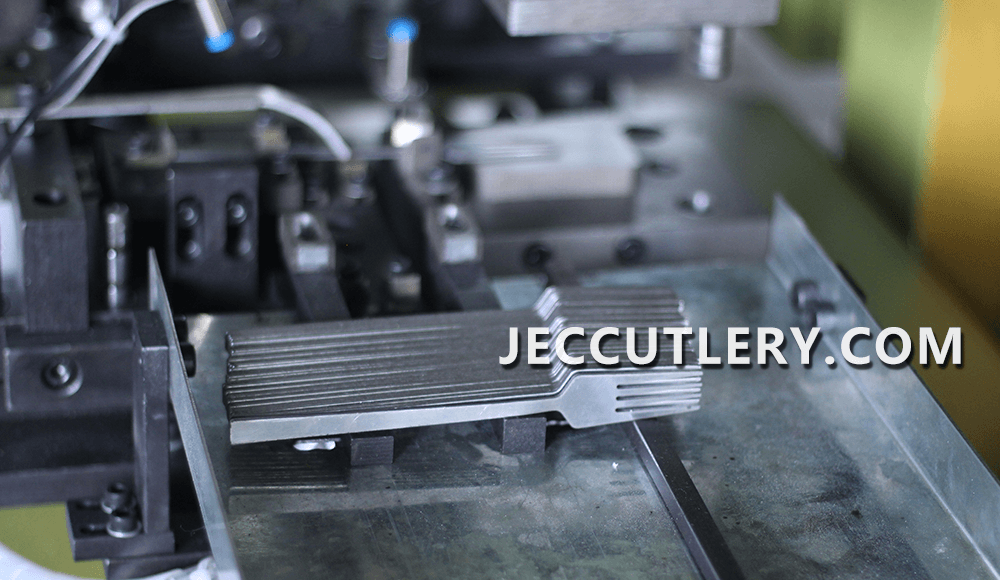

- Cutting and Stamping: Cut the stainless steel into small pieces called “blanks.” Stamp these blanks into the basic shape of a fork. Powerful machines press the steel to form the fork blank.

- Shaping and Forming: After stamping, the fork goes through shaping processes. Trimming the tines to the right length and sharpening. The handle is shaped for comfort. This step is key to making the fork both useful and comfortable.

What Quality Control Measures Are Employed in the Fork Production Process?

Several inspection points are integrated into the production line:

- Material Inspection: Check the stainless steel for defects before production. Use only high-quality material.

- Dimensional Checks: During shaping, the forks are measured to meet exact dimensions. This includes the length of the tines, the thickness of the handle, and the overall balance of the fork.

- Final Inspection: Inspectors check each fork for defects during the final inspection. This includes uneven tines, rough edges, or blemishes. Forks that do not meet the strict quality standards are either reworked or discarded.

How Does Polishing And Finishing Process Enhance Final Product?

Polishing and finishing are the last steps in making forks. These steps are important for both look and use. After shaping, forks often look dull and may have small flaws.

- Polishing: Polish the forks to remove flaws. Use abrasive belts or polishing wheels to smooth the metal. The result is a fork that looks good and feels smooth.

- Final Coating: Sometimes, add a final coating to the forks. This improves their look and protects them from tarnishing. It could be an extra layer of chromium or a different protective coating. This adds shine and durability.

- Packaging: After polishing and finishing, the forks are carefully packaged. This prevents damage during transportation. Group the forks in sets. Wrap each set in protective materials and then box them for distribution.

Influence Of Modern Technology On Fork Manufacturing

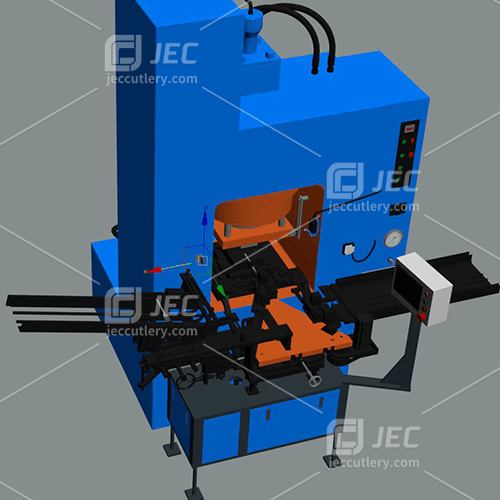

Modern technology has revolutionized fork manufacturing, making it more efficient and precise:

- Automation and Robotics: Automated systems speed up production and make it more consistent. They also reduce human error.

- Advances in Materials Science: Research is developing new stainless steel alloys. These alloys have better properties.

- Future Trends: cutlery manufacturing may soon use AI and machine learning. This will improve production and quality control.

In conclusion, manufacturing stainless steel forks combines old and new methods. Use traditional metalworking techniques alongside modern technology.

Each step in making stainless steel forks is important. It starts with choosing high-quality steel and ends with polishing and inspection. This ensures the product is both useful and attractive.

Understanding this process helps us appreciate the utensils we use every day. It also shows the skill and craftsmanship needed to make them.

Whether you’re a manufacturer, a chef, or just curious, this guide covers the entire fork-making process. By following these steps and checking quality carefully, manufacturers can make high-quality stainless steel forks. These forks will meet the needs of consumers around the world.

A quick overview of the topics covered in this article.