How It Is Made: The Stainless Steel Cutlery Manufacturing Process Unveiled

A quick overview of the topics covered in this article.

Stainless steel tableware has become a must-have in the modern kitchen, and in this exploration, we uncover the subtle journey of how stainless steel cutlery comes to life.

Brief Overview of Stainless Steel Cutlery

Stainless steel tableware stands as a testament to durability, functionality, and aesthetic appeal. The meticulous process behind its creation intertwines artistry and engineering. As we delve into the manufacturing journey, it becomes evident why stainless steel has become the material of choice for discerning tableware enthusiasts.

Selection Of Stainless Steel Raw Material Grades

The genesis of the manufacturing process lies in the critical decision of selecting a stainless steel grade. Each grade offers unique properties such as corrosion resistance, strength and aesthetics. Manufacturers carefully select grades based on the desired properties of the final product.

The alloying process is the alchemical mixing of metals to form a stainless steel alloy with specific properties. Elements such as chromium, nickel and molybdenum are introduced in precise proportions to impart corrosion resistance, hardness and heat resistance. The careful combination of these elements lays the foundation for the excellent quality of stainless steel tableware.

What is the manufacturing process of stainless steel cutlery?

Given that various grades of stainless steel cutlery involve distinct production and processing methods, let’s briefly explore the manufacturing process of a stainless steel spoons. In this case, we will use 410 stainless steel plates as our starting material. The production process is as follows.

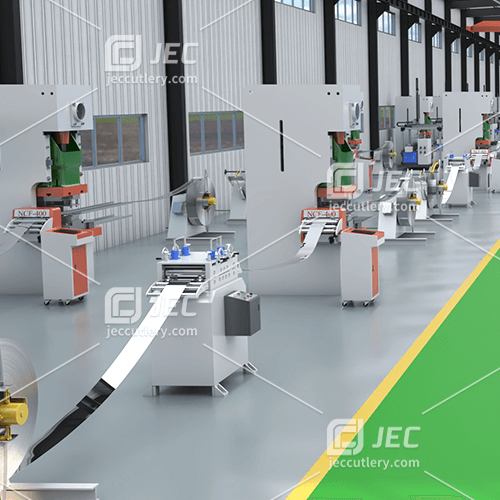

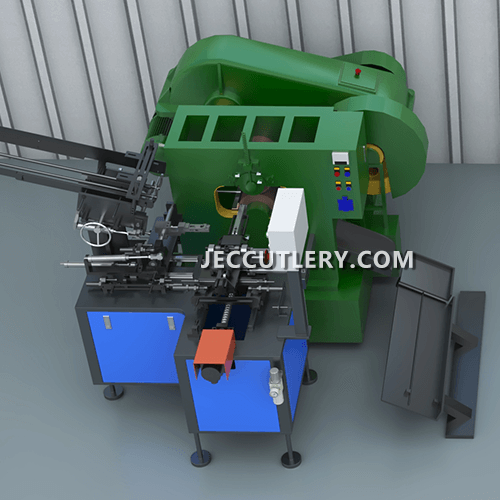

- Cutting: Use an 80T/125T precision punching press and a cutting mold to cut the material to obtain the blanks.

- Extending: Use a φ300 cross rolling machine to extrude the blanks punched out in the previous step.

- Trimming: Use punch press, automatic machine and trimming mold to accurately trim the thinned spoon blanks after cross rolling.

- Polishing and cleaning of flat blanks: edge grinding and surface polishing of semi-finished products, and then use automatic cleaning to clean the wax stains on the surface of the flat spoon blanks.

- Forming: Use a 300T/500T hydraulic press and automatic feeding machine to emboss and form the cleaned blanks.

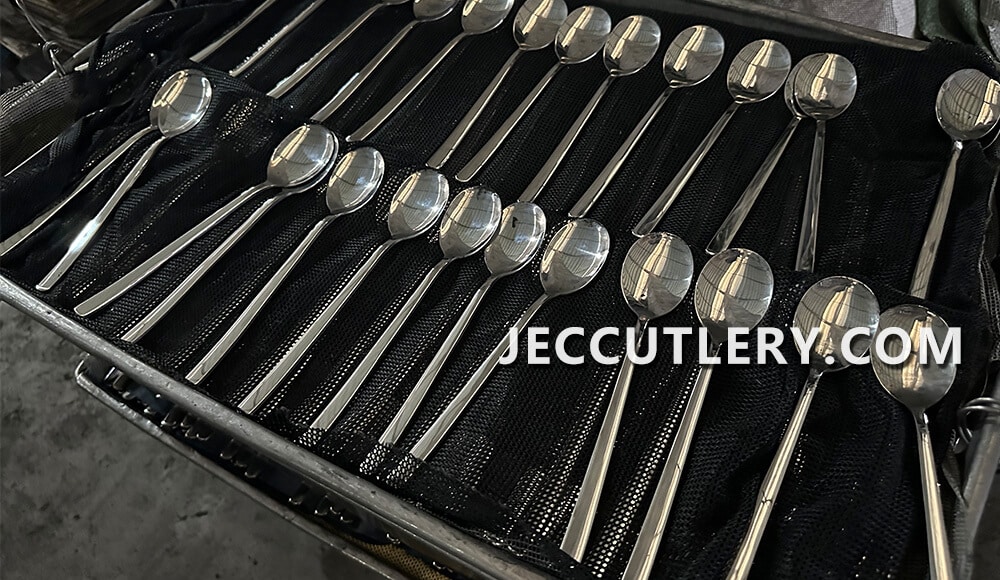

- Finished product polishing: Use a single-axis polishing machine, a double-axis polishing machine, and an S type polishing machine to polish the flat surface and curved surface of the formed spoon in sequence until there are no pitting spots and the surface is shiny.

- Cleaning: Clean the polished finished product with an ultrasonic cleaning machine to remove surface wax stains, oil stains and other dirt. Finally wrap it.

In conclusion, stainless steel has various processing techniques from raw materials to exquisite tableware. Tailor-made for different grades and styles, from cutting to shaping and multi-level polishing technology to ensure perfect surface effects, making stainless steel tableware a visual and tactile enjoyment.

A quick overview of the topics covered in this article.