Hydraulic Presses: Mechanisms, Applications In Cutlery Production

A quick overview of the topics covered in this article.

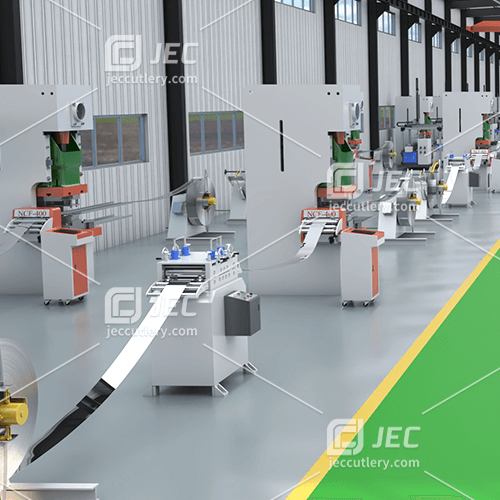

In the world of manufacturing, hydraulic presses stand out as powerful and versatile tools. Whether you’re forging intricate cutlery or crafting robust automotive parts, these machines are indispensable. Let’s delve into the essentials of hydraulic presses, how they work, their specific use in cutlery manufacturing, and the advantages they offer.

What Is A Hydraulic Press?

It’s a machine that uses a hydraulic piston to generate a compressive force. It works based on Pascal’s Law, meaning the pressure applied to a confined fluid spreads out equally in all directions. This principle allows hydraulic presses to exert a tremendous amount of force with relatively little input effort.

Hydraulic presses are used everywhere, from automotive to aerospace and even in making cutlery. They apply steady and precise pressure, perfect for tasks that require careful attention to detail and consistency.

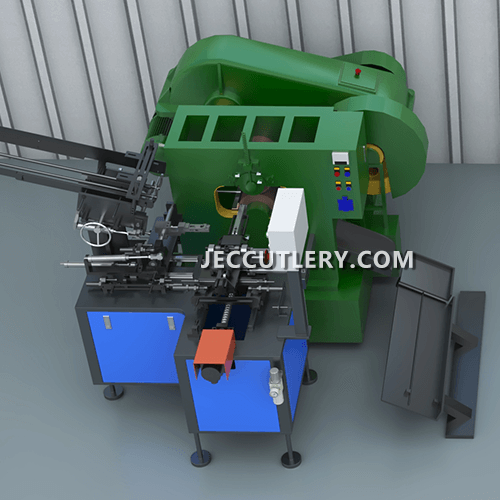

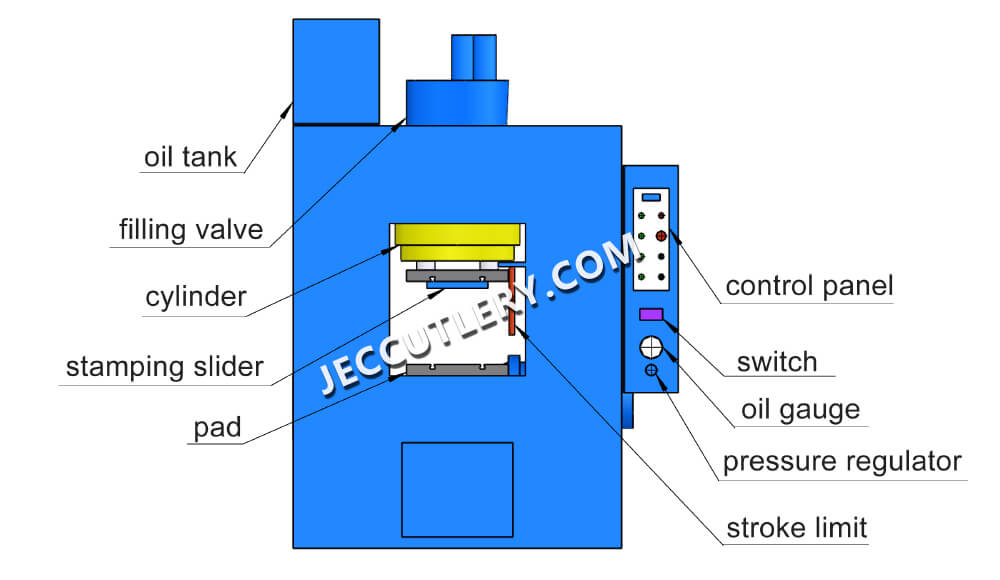

How Does A Hydraulic Press Work?

The key component of a hydraulic press is its hydraulic system, made up of two cylinders: a larger main cylinder and a smaller slave cylinder. The process begins with hydraulic fluid being pumped into the smaller cylinder. Due to Pascal’s law, this pressure is transferred through the fluid and amplified in the larger cylinder.

Here’s a breakdown of how it works:

- Hydraulic Fluid Injection: High-pressure fluid is injected into the smaller cylinder.

- Pressure Transmission: The pressure from the smaller cylinder is conveyed through the fluid to the larger cylinder.

- Force Application: The larger cylinder exerts a substantial force on the piston, which then applies pressure to the workpiece.

This mechanism allows hydraulic presses to achieve remarkable precision and force, making them suitable for a variety of tasks, from metal forming to material testing.

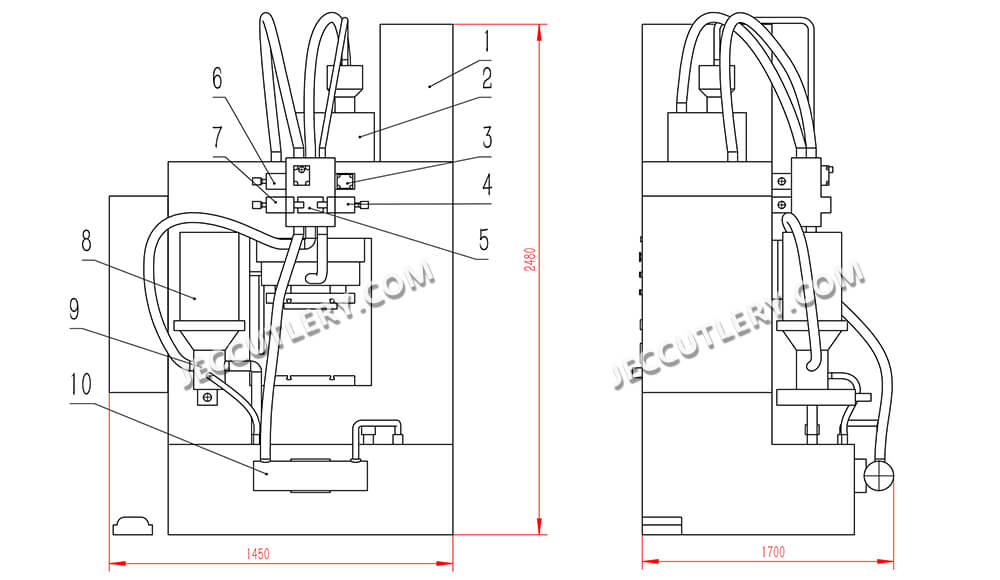

What Is An H Frame Hydraulic Press And How Is It Used?

An H frame hydraulic press, named for its distinctive “H” shape, is a popular type of hydraulic press. The design includes two vertical columns and a horizontal beam, creating an “H” when viewed from the front. This structure offers exceptional stability and balance, making it ideal for tasks that require uniform pressure distribution.

H frame presses are widely used in industries that need precise metal forming and fabrication. Their applications include:

• Forging: Shaping metal parts through compressive force.

• Bending: Altering the shape of metal sheets without changing their volume.

• Punching: Creating holes or indents in metal sheets.

In cutlery manufacturing, H frame hydraulic presses are used to forge and shape blades, ensuring each piece meets exact specifications with consistent quality.

Applications Of Hydraulic Presses In Cutlery Manufacturing

Hydraulic presses play a crucial role in the cutlery manufacturing process. Here’s how they are utilized:

- Forging Blades: Hydraulic presses are used to forge knife and fork blades from metal blanks. The consistent force ensures that each blade is shaped precisely, maintaining uniform thickness and strength.

- Stamping: Stamping involves imprinting designs or logos onto cutlery. Hydraulic presses provide the necessary pressure to create clear and durable impressions without damaging the metal.

- Forming Handles: For cutlery that includes intricate handle designs, hydraulic presses shape the handles to ergonomic and aesthetic specifications.

The precision and control offered by hydraulic presses ensure that every piece of cutlery is crafted to perfection, meeting both functional and aesthetic standards.

Advantages Of Using Hydraulic Presses

Hydraulic presses offer several advantages that make them a preferred choice in various manufacturing processes:

- Precision and Control: The ability to finely control the pressure allows for precise shaping and forming of materials, which is crucial in industries like cutlery manufacturing.

- Versatility: Hydraulic presses can perform a wide range of operations, including forging, bending, punching, and stamping, making them versatile tools in any manufacturing setup.

- Cost-Effectiveness: Although hydraulic presses require a significant initial investment, they prove to be economical over time because of their durability and minimal maintenance needs.

- Power Amplification: They can amplify a small input force into a large output force, making them capable of handling heavy-duty tasks with ease.

- Safety and Noise Reduction: Hydraulic presses operate more quietly and smoothly compared to mechanical presses, and modern systems often include safety features that protect operators from accidents.

In conclusion, hydraulic presses are vital in modern manufacturing, offering unmatched precision, versatility, and power. In cutlery manufacturing, they ensure that every piece is crafted with accuracy and consistency, from the blade to the handle. Understanding how these machines work and their benefits can help industries leverage their full potential, ensuring high-quality production and efficiency.

Whether you’re in the automotive, aerospace, or cutlery manufacturing industry, hydraulic presses are indispensable tools that can enhance your production capabilities and ensure superior product quality.

A quick overview of the topics covered in this article.