What Is A Punch Press Machine

A quick overview of the topics covered in this article.

A punch press is a vital machine in metalworking. It cuts, punches, or bends materials with precision. It uses a die to apply significant force to shape materials. It is essential in manufacturing for the cutlery, automotive, and hardware industries.

Want to know how a punch press works? What makes it different from similar machines? And what is its role in modern manufacturing? Let’s dive deeper into the details.

What Does A Punch Press Do?

A punch press does many metalworking tasks. It can punch holes, cut shapes, and bend materials into desired forms. The machine applies consistent pressure through a die. This ensures speed, accuracy, and repeatability in manufacturing.

A punch press is essential for businesses. It will improve efficiency and product consistency. Its versatility allows it to meet diverse production needs. These range from mass-producing cutlery to making custom hardware parts.

What Is The Difference Between A Stamp Press And A Punch Press?

Both stamp presses and punch presses are used in metalworking. But their purposes differ. A punch press makes holes and simple cuts. A stamp press forms complex shapes, like embossing or deep drawing.

Understanding these differences ensures manufacturers choose the right equipment for their production needs. A punch press is precise and efficient. A stamp press is better for intricate designs and detailed shaping tasks.

Is A Punch Press A CNC Machine?

Traditional punch presses operate manually or with some automation. Modern versions use CNC (Computer Numerical Control) technology. CNC punch presses enable automated operations, offering unmatched precision and efficiency.

CNC punch presses give manufacturers a competitive edge. They improve productivity and reduce manual work. They can perform complex tasks with little human oversight. This ensures consistent, high-quality results.

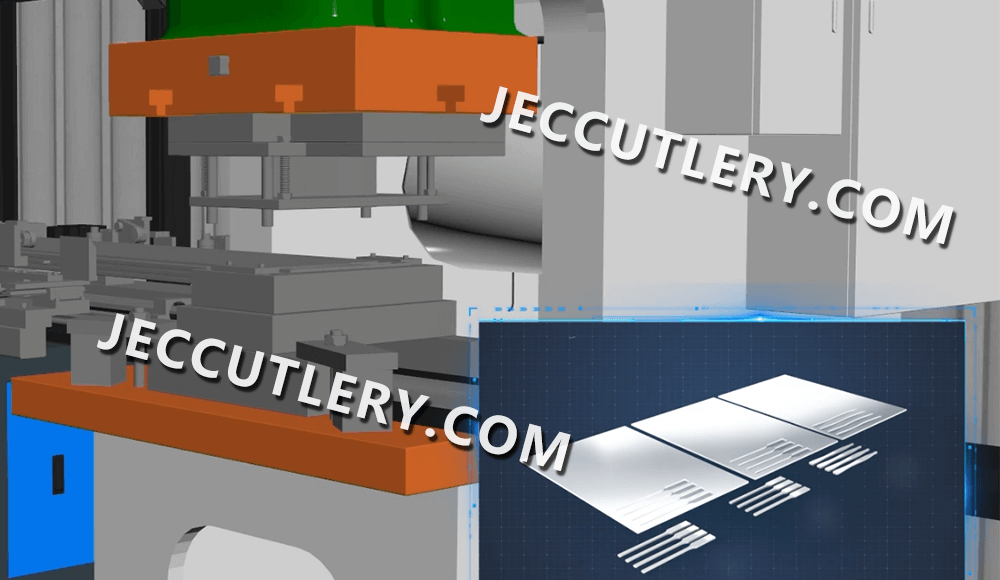

What Is The Punch Press Technique?

The punch press technique uses a die to apply force to a material. It cuts or shapes it to meet specific requirements. This method is known for its accuracy and speed, making it a preferred choice for mass production.

Mastering this technique helps manufacturers get consistent results. It cuts waste and boosts efficiency. Industries, like stainless steel cutlery, rely on this technique. It helps them craft precise, durable products.

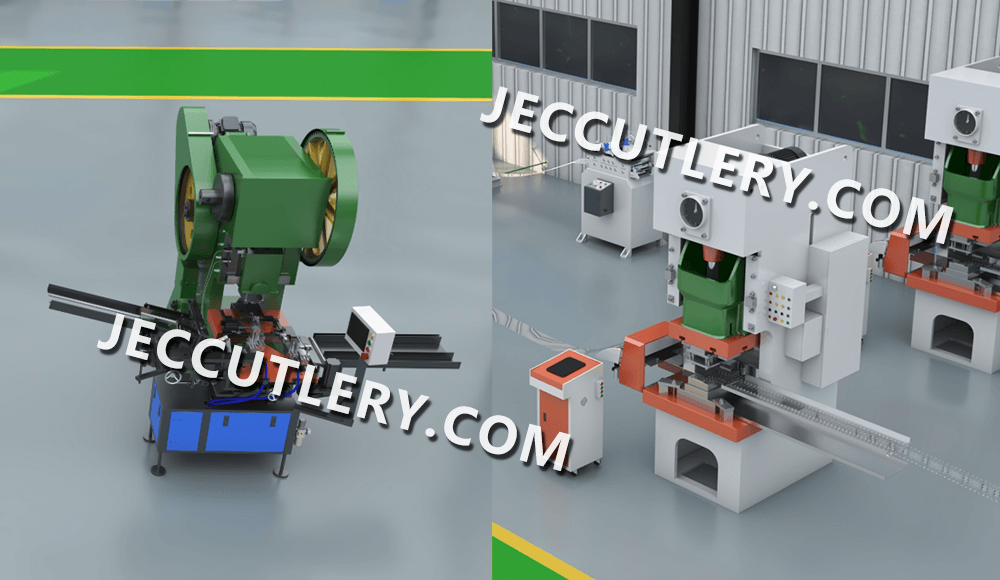

What Are The Main Types Of Punch Presses?

Punch presses are categorised into mechanical and hydraulic types. Mechanical punch presses run at high speed. They are ideal for mass production. Hydraulic punch machines, however, are versatile and precise. They are suitable for tasks needing flexibility.

Selecting the right type of punch press depends on the specific needs of the production line. Mechanical models are fast and efficient. Hydraulic models are better for complex designs.

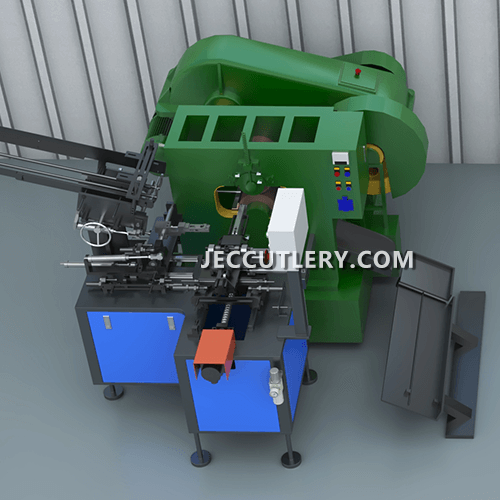

How Does A Punch Press Work?

A punch press positions the material under the tooling mold. It then applies force to punch, cut, or bend it. The mold’s design shapes the material. This ensures precision and consistency.

This straightforward yet effective mechanism makes punch presses indispensable in various manufacturing sectors. By automating repetitive tasks, they enhance productivity and lessen manual labour.

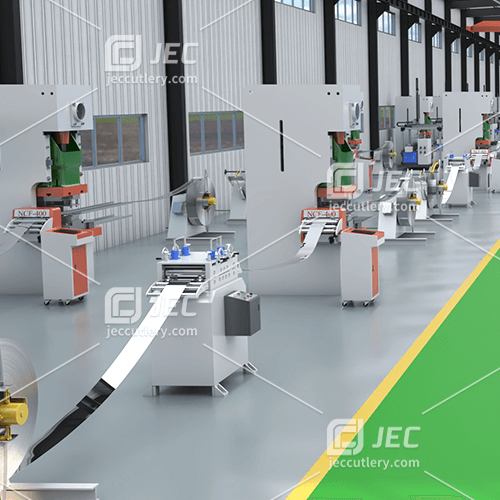

What Industries Use Punch Presses?

Punch presses are essential in many industries. They are used in making stainless steel cutlery, automotive parts, and electrical components. Their high-speed, precise metalworking makes them a valuable asset in mass production.

For example, in the cutlery industry, punch presses craft forks, spoons, and knives. They ensure uniform dimensions and smooth finishes. In the automotive sector, they are vital for making durable, complex metal parts.

In conclusion, A punch press is vital for modern manufacturing. It offers precision, efficiency, and versatility. Its applications span many industries, driving innovation in metalworking. Whether for punching, cutting, or bending, it is used everywhere.

A quick overview of the topics covered in this article.